- Home Page

- Company Profile

-

Our Products

- Servo Drive Motors

- Digital Temperature Controller

- AC Drives

- Process Controllers

- Human Machine Interface

- Analytical Instruments

- Programmable Logic Controller

- Servo Amplifier

- Digital PH Meter

- Ph Electrode

- Pressure Transducers

- Temperature Recorder

- Preset Counter

- pH Testers

- Programmable Controller

- Operator Panels

- Air Particle Counter

- Injection Mold Controllers

- Pressure Transmitter

- ORP Electrodes

- Pressure Switches

- Solenoid Valves

- Level Sensors

- Industrial Router

- Hot Runner

- Data Loggers

- Remote Monitoring System

- Profile Controller

- Resin Pressure Sensors

- Yaskawa AC Drives

- Servo Motor

- Dew Point sensor

- Moisture In Oil Sensor

- Co2 sensor

- Air velocity sensor

- Infrared Thermometers

- Variable Speed Drives

- Vector Drive

- Ph Meter

- Conductivity Controller

- Paperless Recorder

- Pressure Monitor

- Manometer

- TDS Tester

- Servo Controller

- PID Controller

- Pressure Transducer

- Humidity Transmitter

- Communication Converter

- Air Quality Monitor

- Applications & Business area

- Solutions

- Contact Us

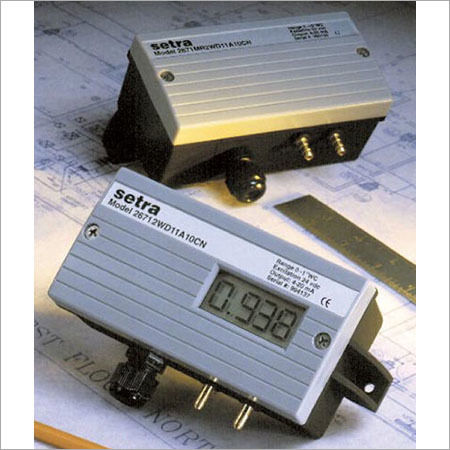

Differential Pressure Transmitters

5000 INR/Piece

Product Details:

- Capacity 1000 mbar maximum

- Current Range 4-20 mA

- Resolution 0.1 mbar

- Temperature Range -20C to +80C

- Connectivity Type 2-wire/4-wire

- Sensor Type Piezoresistive

- Pressure Range -1000 mbar to +1000 mbar

- Click to View more

X

Differential Pressure Transmitters Price And Quantity

- 1 , , Piece

- 5000 INR/Piece

Differential Pressure Transmitters Product Specifications

- 0.2% of full scale

- -1000 mbar to +1000 mbar

- 0-95% RH (non-condensing)

- 0 - 1000 mbar

- Stainless Steel

- 0 to 1000 mbar

- -20C to +80C

- 1000 mbar maximum

- 4-20 mA

- 0.1 mbar

- 12-36V DC

- LED Digital Display

- < 2W

- 2-wire/4-wire

- Piezoresistive

Differential Pressure Transmitters Trade Information

- 2 , , Piece Per Week

- 1-2 Days

Product Description

Differential Pressure Transmitter has wide applications in power generation plants, petrochemical engineering, sewage disposal and in other industries. Die cast aluminium made housing of this transmitter is burst protected, weather proof and powder coated. Its V/I integrated circuit can be installed quickly. Integrated LCD display screen of this product has high resolution level and its advanced design is suitable for real time monitoring job. Maximum storage temperature of this high precision Differential Pressure Transmitter is 110 degree C. Parameters of this transmitter can be set directly by using keypads. Its press button can be used for zero calibration job automatically.

Reliable Differential Pressure Measurement

Experience accurate differential pressure monitoring with a resolution of 0.1 mbar and a swift response time under 1 second. The transmitters stainless steel design ensures long-term durability in industrial environments, complemented by an IP65 ingress protection rating to safeguard against dust and water. Its adaptability supports both field and panel mounting, offering valuable flexibility for installation in various settings.

User-Friendly Operation and Maintenance

This transmitter features a digital LED display for clear, immediate readings. Factory calibration allows for rapid deployment, while push-button and remote-configurable zero/span adjustments simplify maintenance. The device is compatible with HART protocol for seamless remote monitoring and parameterization, ensuring ease of integration into existing control systems.

FAQs of Differential Pressure Transmitters:

Q: How is the Differential Pressure Transmitter installed for optimal performance?

A: The transmitter can be mounted on either a panel or directly in the field as per application requirements. Ensure a secure connection using the 1/4" NPT female process connection and follow the supplied guidelines for power (12-36V DC) and wiring (2-wire or 4-wire) to achieve the best performance and reliability.Q: What are the benefits of the IP65 ingress protection for this transmitter?

A: IP65 ingress protection ensures the transmitter is shielded against dust and low-pressure water jets, making it suitable for harsh industrial environments. This protection maximizes operational reliability and reduces maintenance needs in challenging conditions.Q: Can I adjust the zero and span settings on-site, and what methods are available?

A: Yes, the transmitter is both factory calibrated and field adjustable. Zero and span can be configured through push-button controls on the device or remotely, allowing for quick recalibration and precise setup directly at your site.Q: Where is this differential pressure transmitter best utilized?

A: It is ideally suited for industrial applications such as process control, HVAC systems, and filtration monitoring, where accurate pressure measurement within 0-1000 mbar is essential. Its robust design and flexible mounting options make it adaptable to various industrial settings.Q: What is the typical process for integrating the transmitter with existing control systems?

A: Connect the device using standard 4-20 mA wiring for output and utilize the HART protocol if remote monitoring or configuration is required. The digital LED display offers instant local feedback, aiding both setup and operational monitoring.Q: What should be considered regarding ambient conditions when operating this device?

A: Operate the transmitter within the specified ambient temperature range of -20C to 60C and humidity of 0-95% RH (non-condensing). For higher safety demands, such as hazardous locations, an explosion-proof version is available upon request.Q: Why choose a piezoresistive sensor type for this transmitter?

A: Piezoresistive sensor technology provides stable, accurate measurement with low power consumption (<2W) and excellent responsiveness, making it highly suitable for continuous, precise differential pressure monitoring in industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pressure Transmitter' category

|

MIFA SYSTEMS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |