- Home Page

- Company Profile

-

Our Products

- Servo Drive Motors

- Digital Temperature Controller

- AC Drives

- Process Controllers

- Analytical Instruments

- Human Machine Interface

- Programmable Logic Controller

- Servo Amplifier

- Digital PH Meter

- Ph Electrode

- Pressure Transducers

- Temperature Recorder

- Preset Counter

- pH Testers

- Programmable Controller

- Operator Panels

- Air Particle Counter

- Injection Mold Controllers

- Pressure Transmitter

- ORP Electrodes

- Pressure Switches

- Solenoid Valves

- Level Sensors

- Industrial Router

- Hot Runner

- Data Loggers

- Remote Monitoring System

- Profile Controller

- Resin Pressure Sensors

- Yaskawa AC Drives

- Servo Motor

- Dew Point sensor

- Moisture In Oil Sensor

- Co2 sensor

- Air velocity sensor

- Infrared Thermometers

- Variable Speed Drives

- Vector Drive

- Ph Meter

- Conductivity Controller

- Paperless Recorder

- Pressure Monitor

- Manometer

- TDS Tester

- Servo Controller

- PID Controller

- Pressure Transducer

- Humidity Transmitter

- Communication Converter

- Air Quality Monitor

- Applications & Business area

- Solutions

- Contact Us

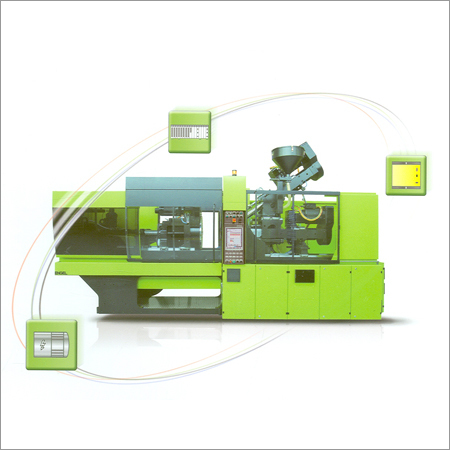

Injection Molding PLC Controller

150000 INR/Unit

Product Details:

X

Injection Molding PLC Controller Price And Quantity

- 1 Unit

- 150000 INR/Unit

Injection Molding PLC Controller Trade Information

- Ahmedabad

- Cash Against Delivery (CAD), Cash Advance (CA), Letter of Credit (L/C), Cash in Advance (CID), Cheque

- 500 Unit Per Day

- 1-2 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Carton Box.

- All India

Product Description

Owing to our experience & skills in this sector, we have been successfully engaged in distributing a wide gamut of Injection Molding Controller. All our molding controllers are designed to stop operating in high voltage. We make available all these Injection Moulding Machine Controller with fully injection molding machines. The offered Injection Moulding Machine PLC Controller have active front end and thereby provides an energy balance via a shared DC link. Easy to operate, these controllers are offered to the clients at competitive prices.

Further Details

- A Complete Retro Solution, A Very Low End Economic Solution To Very Complex Integrated Solution.

-

Mifa System can give complete solution for energy saving in injection molding machine Controller like advance micro controller based controller along with servo motors,servo drives and hydraulic pumps.

PLC Injection Molding Machines :

With the i1000, i2000 and i5000 solutions, KePlast offers a complee and ideally coordinated control, drive and safety technology package. This renders obsolete he difficulties with regard to the combination of differing components, such as compatibility problems and the related costs, incurred to date by mechanical engineers.

Top-Class controls

The control systems of the i2000 and i5000 series stand out due to their precision and high productivity and ensure economic energy consumption. Precision is provided by fast controller cycle times, while increased productivity can be achieved due to he outstanding performance of the controls using movement parallelisation.

High- performance drive technology

KeDrive D4 and D6 drive systems are available for fully electric injection molding machines. The drives are cost-efficient and with up to 350A current peaks offer especially high dynamism levels. In addition, they are extremely economic to operate as they have an active front end and can provide an energy balance via a shared DC link

Maure safety technology

KePlast offers a comprehensive safety solution for fully electric injection molding machines, which consists of integrated drive safety functions and safety module. In addition to effective protection for both man and machinery, its straightforward design ensures robustness with regard to defects. Moreover, installation times are effectively reduced, thus creating cos savings. In combination with the especially high degree of safety functionality already inherent to KePlast, the entire machine can be easily certificated in line with all standard safety norms.

During the preparation of control applications in dialog form, he ergonomic KePlast Application Composer software tool guides the machine manufacturer through the entire configuration process up to the finished control program, without the necessity of programming skills.

Fully programmed software elements

In an initial step, the manufacture defines the equipment of the machine quickly and simply by selecting the fully programmed elements from the KEBA library

- Injection unit

- Ejector

- Cores

- Hot runner controller

- Clamp unit

- Robot interface

Specification:

Operator Panel:

- Portrait format display

- Contactless user identification by RFID-card

K2-200 High-performance module:

- Latest INTEL High-End M-CPU: Celeron M 600 Pentium M 1,4 GHz

- Wide range of CPU power

- Inject to hold detection 100 us

- Up to 200 we closed loop scan time

- Standard I/Os included

- K-Net High speed field bus

Seamless Control for Industrial Injection Molding

Engineered to offer accurate control of molding parameters, this PLC controller is fundamental in maintaining consistency and quality across industrial manufacturing. Its programmable logic controller (PLC) system allows precise scheduling and temperature adjustment, essential for complex molding requirements.

Built for Industrial Reliability and Versatility

Manufactured from durable ABS plastic and featuring a rectangular ergonomic design, this controller withstands rigorous factory settings. It integrates efficiently with existing machinery, providing a seamless interface between human operators and automated molding systems.

FAQ's of Injection Molding PLC Controller:

Q: How does the Injection Molding PLC Controller enhance manufacturing processes?

A: The controller automates the regulation of time and temperature in the injection molding cycle, minimizing errors and ensuring a consistent product outcome. Its PLC programming allows for easy setting adjustments, contributing to higher product quality and operational efficiency.Q: What materials and design features make this controller suitable for industrial use?

A: Constructed from strong ABS plastic and shaped in a robust rectangle, the controller is resistant to wear, impact, and harsh factory environments. Its industrial-grade design ensures reliable performance over prolonged usage.Q: When should I use a PLC Controller in injection molding applications?

A: Utilize this controller when you require precise management of cycle parameters to guarantee product uniformity, or when automating processes for higher productivity and traceability in industrial settings.Q: Where can I integrate this Injection Molding PLC Controller in my manufacturing setup?

A: This controller can be integrated with standard injection molding machines in factory assembly lines or standalone workstations, offering broad compatibility with devices requiring time and temperature control.Q: What is the process for setting parameters on the controller?

A: Operators can program time and temperature settings via the controller's intuitive PLC interface. Changes can be made quickly on-site, and settings can be stored for repeated use, streamlining operation resets and maintenance.Q: How is the controller beneficial for industrial suppliers and manufacturers in India?

A: By improving automation and accuracy, the controller helps Indian suppliers and manufacturers achieve higher throughput, reduced waste, and enhanced quality control, strengthening their competitiveness in global markets.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Injection Mold Controllers' category

|

MIFA SYSTEMS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |