- Home Page

- Company Profile

-

Our Products

- Servo Drive Motors

- Digital Temperature Controller

- AC Drives

- Process Controllers

- Human Machine Interface

- Analytical Instruments

- Programmable Logic Controller

- Servo Amplifier

- Digital PH Meter

- Ph Electrode

- Pressure Transducers

- Temperature Recorder

- Preset Counter

- pH Testers

- Programmable Controller

- Operator Panels

- Air Particle Counter

- Injection Mold Controllers

- Pressure Transmitter

- ORP Electrodes

- Pressure Switches

- Solenoid Valves

- Level Sensors

- Industrial Router

- Hot Runner

- Data Loggers

- Remote Monitoring System

- Profile Controller

- Resin Pressure Sensors

- Yaskawa AC Drives

- Servo Motor

- Dew Point sensor

- Moisture In Oil Sensor

- Co2 sensor

- Air velocity sensor

- Infrared Thermometers

- Variable Speed Drives

- Vector Drive

- Ph Meter

- Conductivity Controller

- Paperless Recorder

- Pressure Monitor

- Manometer

- TDS Tester

- Servo Controller

- PID Controller

- Pressure Transducer

- Humidity Transmitter

- Communication Converter

- Air Quality Monitor

- Applications & Business area

- Solutions

- Contact Us

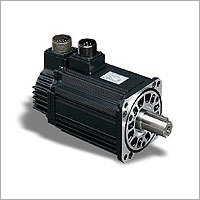

Servo Motors Sigma-II

40000 INR/Unit

Product Details:

- Product Type Servo Motor

- Output Power 415 Volt (v)

- Frequency (MHz) 50 Hertz (HZ)

- Phase Three Phase

- Speed 1500 RPM

- Starting Type Electric Start

- Color Black

- Click to View more

X

Servo Motors Sigma-II Price And Quantity

- 40000 INR/Unit

- 1 Unit

Servo Motors Sigma-II Product Specifications

- Three Phase

- Electric Start

- Servo Motor

- 1500 RPM

- 1 Year

- 50 Hertz (HZ)

- 415 Volt (v)

- Black

Servo Motors Sigma-II Trade Information

- Ahmedabad

- Letter of Credit (L/C), Cash Against Delivery (CAD), Cheque, Cash in Advance (CID), Cash Advance (CA)

- 500 Unit Per Day

- 1-2 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Carton Box.

- All India

Product Description

Leveraging on our extensive experience, we are notorious as one of the most distinguished distributors of Servo Motors Sigma-II. Our long list of clients highly appreciates this servo motors due to its segmented stator design, high efficiency and optimum quality. Our offered servo motors are robust in construction and precise dimensions. These servo motors are ideal for applications requiring optimized load matching. We make sure that our entire gamut of Servo Motors Sigma -II is procured from only renowned and trusted vendors present in market.

Servo Motors Sigma-II Specifications

- Rated Output: 0.45kW, 0.85kW, 1.3kW, 1.8kW, 2.9kW, 4.4kW, 5.5kW, 7.5kW, 11kW, 15kW.

The SGMGH servomotor series has a medium inertia rotor and incorporates the segmented stator design, which dramatically reduces overall size. These servomotors are well suited for applications requiring optimized load matching. There are 10 sizes from 500 watts to 15 kW providing up to 1,988 lb-in (224 Nm) of peak torque. 200 and 400 volt windings are available with rated speeds of 1,500 rpm and maximum speeds of 3,000 rpm (up to 7.5 kW). A 131,072 ppr incremental serial encoder is standard. The low base speed, medium inertia rotor, and high-resolution encoder allow many applications to be solved without a gearbox. The SGMGH is rated IP67 (not including the shaft) providing resistance to moisture. Options include a 131,072 ppr absolute encoder, gearmotor, shaft seal, and holding brake.

Product details

|

Model No |

Millenium 3 CD20 |

|

No Of Inputs |

12 |

|

IP Rating |

IP 20 |

|

Dimension |

59.5 mm x 124.6 mm x 90 mm |

|

Display Type |

Digital |

|

Product Type |

PLC controller |

|

No of outputs |

8 Relay 8A |

Reliable Performance for Industrial Demands

The Sigma-II Servo Motor delivers consistent speed and power for demanding automation tasks. Its 1500 RPM speed and 415V output are tailored for industrial reliability, allowing users to maintain productivity even under heavy workloads. With its electric start and robust black construction, it adapts efficiently to diverse operational environments.

Easy Integration & Support

Designed for seamless compatibility, this servo motor integrates smoothly with three-phase power systems. Manufacturers and suppliers across India provide both pre-sale guidance and post-sale support, ensuring quick installation and peace of mind with a 1-year warranty on all units.

FAQs of Servo Motors Sigma-II:

Q: How do I install the Sigma-II Servo Motor in my equipment?

A: The Sigma-II Servo Motor is designed for straightforward installation on three-phase systems. Ensure you connect the motor to a compatible 415V power source, following your equipments integration guidelines. For detailed instructions, refer to the manual or consult with the supplier in India.Q: What types of applications can benefit from using this servo motor?

A: This servo motor is ideal for CNC machinery, conveyors, robotics, textile equipment, and other automation systems requiring precise speed and torque control at 1500 RPM and 50 Hz.Q: When should the Sigma-II Servo Motor undergo routine maintenance?

A: It is recommended to inspect and maintain the Sigma-II Servo Motor every six months or according to your operations workload and environment. Regular checks ensure optimal performance and extend the motors lifespan.Q: Where can I purchase authentic Sigma-II Servo Motors in India?

A: Genuine Sigma-II Servo Motors are available from authorized manufacturers and suppliers throughout India. Always purchase from recognized vendors to secure warranty coverage and support.Q: What is the process for claiming warranty service if an issue arises?

A: In case of a malfunction covered by the 1-year warranty, contact your supplier or manufacturer with proof of purchase and a description of the issue. They will guide you through the service or replacement process in accordance with warranty terms.Q: How does using this servo motor benefit industrial automation?

A: The Sigma-II Servo Motor enhances automation by providing reliable, accurate motion control, reducing downtime and maintenance needs. Its electric start and three-phase operation ensure smooth, energy-efficient performance in demanding settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Servo Drive Motors' category

|

MIFA SYSTEMS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |